In today's competitive business environment, 5S training, rooted in lean management principles, is a powerful solution for enhancing workplace organization and productivity. This systematic approach, focusing on sorting, setting in order, cleaning (shining), standardizing, and sustaining, creates an efficient environment. By implementing 5s continuous improvement methodologies, businesses can streamline processes, reduce waste, and boost overall efficiency through process standardization. This fosters a culture of order, discipline, and collaboration, improving safety and job satisfaction.

“Boosting productivity is every business’s goal, and an effective system is key. This article explores a powerful tool—5S training—rooted in Lean Management principles, which can transform any workspace. By implementing structured organization and process standardization, businesses can achieve remarkable efficiency. We’ll delve into how 5S fosters continuous improvement, ensuring sustained productivity levels. Discover the art of streamlining workflows and cultivating an environment that encourages ongoing enhancements, leading to long-term success.”

- Understanding the Foundation: 5S Training and Lean Management Principles

- Implementing Efficient Systems: Workplace Organization and Process Standardization

- Cultivating Continuous Improvement: The Role of 5S in Sustaining Productivity

Understanding the Foundation: 5S Training and Lean Management Principles

In today’s competitive business landscape, enhancing productivity through efficient workplace organization is paramount. A powerful tool in this regard is 5S training, a practice rooted in Lean Management principles. This systematic approach focuses on sorting, setting in order, shining (cleaning), standardizing, and sustaining to create an environment conducive to optimal performance. By implementing 5S continuous improvement methodologies, businesses can streamline processes, reduce waste, and improve overall efficiency.

The foundation of this strategy lies in the meticulous process standardization that 5S training provides. It encourages a culture of order and discipline where every tool, material, and task has its designated place and purpose. This organizational framework not only enhances productivity but also fosters a safer and more collaborative work environment. Through lean management techniques, teams can identify and eliminate bottlenecks, leading to improved workflow and increased job satisfaction.

Implementing Efficient Systems: Workplace Organization and Process Standardization

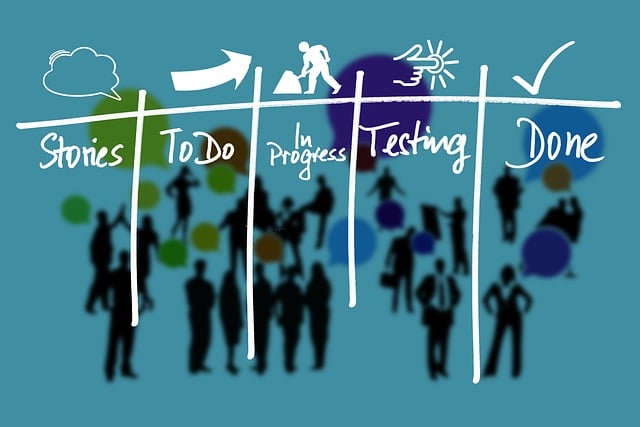

Implementing efficient systems is a cornerstone of any productivity enhancement strategy. One powerful approach is integrating 5S training and lean management principles into daily operations. 5S, a methodology rooted in Japanese manufacturing, focuses on sorting, organizing, cleaning, standardizing, and sustaining an environment that promotes efficiency and safety. This involves meticulously arranging tools and materials to minimize waste and maximize accessibility, fostering a culture of continuous improvement.

Workplace organization is not just about aesthetics; it directly impacts productivity. Standardizing processes ensures tasks are completed consistently and efficiently. By defining clear steps for each workflow, teams can streamline operations, reduce errors, and identify bottlenecks. This standardization acts as a foundation for further improvements, enabling organizations to adapt and grow while maintaining high productivity levels.

Cultivating Continuous Improvement: The Role of 5S in Sustaining Productivity

Cultivating Continuous Improvement: The Role of 5S in Sustaining Productivity

In today’s competitive business landscape, maintaining and enhancing productivity is crucial for success. One highly effective approach that integrates seamlessly with lean management principles is 5S training. This methodology focuses on workplace organization and process standardization by implementing five simple yet powerful steps: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By fostering a culture of continuous improvement through 5S continuous improvement practices, organizations can achieve remarkable efficiency gains.

The benefits of 5S training extend far beyond immediate workplace organization. It promotes a disciplined mindset among employees, encouraging them to constantly evaluate and optimize their work processes. This lean management approach not only streamlines operations but also enhances overall productivity by minimizing waste and maximizing resource utilization. By adopting 5S, organizations can create an environment that supports sustained productivity growth, ensuring they stay ahead in the market.

By integrating 5S training and Lean Management principles, organizations can achieve remarkable productivity gains. Implementing efficient systems through workplace organization and process standardization creates a solid foundation for success. Cultivate a culture of continuous improvement led by 5S practices to sustain these enhancements over time. Adopting these strategies ensures businesses remain competitive and thrive in today’s fast-paced environment.