Ergonomic workplace design, driven by 5S training and lean management principles, optimizes human-environment interaction for enhanced productivity and well-being. By implementing sorting, setting in order, cleaning (shining), standardizing, and sustaining practices, workplaces achieve efficient organization, reduce injuries, and boost job satisfaction. Process standardization minimizes repetitive strain injuries, fostering a culture of continuous improvement that drives business success while enhancing employee comfort and retention. Regular reviews adapt the workspace to changing needs, ensuring a dynamic yet productive environment. In today's digital age, this approach is crucial for achieving and maintaining ergonomic design through seamless integration of ergonomic principles into daily operations.

Ergonomic workspace design is no longer a nicety—it’s a necessity. As we spend increasingly more hours at our desks, understanding ergonomics and its impact on workplace design has become critical to prevent injury, boost productivity, and foster employee well-being. This article explores proven strategies like 5S training for efficient organization, lean management principles for streamlined layouts, and the power of continuous improvement. We also delve into process standardization as a key to sustainable ergonomic environments.

- Understanding Ergonomics and its Impact on Workplace Design

- Implementing 5S Training for Efficient Workspace Organization

- Lean Management Principles to Enhance Workplace Layout

- The Role of Continuous Improvement in Creating an Ergonomic Environment

- Process Standardization: A Key Strategy for Sustainable Workspace Ergonomics

Understanding Ergonomics and its Impact on Workplace Design

Ergonomics plays a pivotal role in shaping modern workplace design, focusing on optimizing the interaction between humans and their work environment to enhance productivity, reduce strain, and promote overall well-being. By understanding the principles of ergonomics, designers can create spaces that accommodate the natural movements and capabilities of workers, thereby reducing occupational injuries and improving job satisfaction. This involves considering factors such as chair design, desk layouts, lighting, and equipment placement to ensure a comfortable and functional workspace.

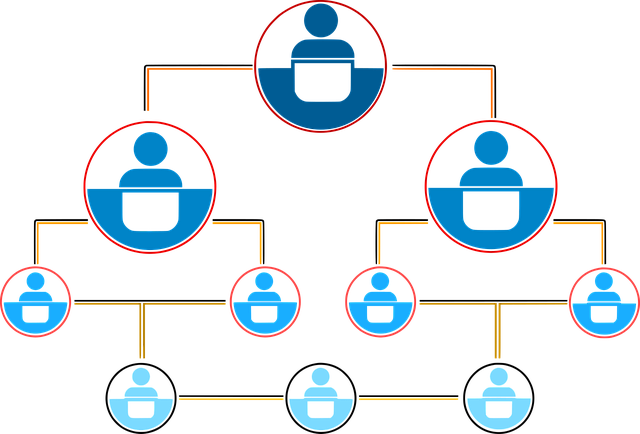

Incorporating ergonomic practices aligns seamlessly with concepts like 5S training, lean management, and workplace organization. The 5S continuous improvement methodology emphasizes sorting, setting in order, shining (cleaning), standardizing, and sustaining, all of which contribute to creating an efficient, streamlined work environment. Process standardization, a key aspect of lean management, ensures that tasks are executed consistently and safely, minimizing the risk of repetitive strain injuries often associated with poor ergonomics. By integrating these principles, organizations can foster a culture of workplace wellness and productivity, ensuring their staff operates at peak performance while maintaining a healthy and engaged workforce.

Implementing 5S Training for Efficient Workspace Organization

Implementing 5S Training for Efficient Workspace Organization

In today’s digital era, optimizing workspace design through 5S training is a game-changer for enhancing productivity and employee satisfaction. This lean management philosophy, rooted in process standardization, focuses on sorting, setting in order, shining (cleaning), standardizing, and sustaining. By instilling these principles, workplaces can transform into streamlined environments where every tool and material has its designated place, minimizing clutter and maximizing efficiency.

The 5S continuous improvement methodology encourages regular audits to maintain an organized workspace. Training employees in this system fosters a culture of accountability, where everyone takes pride in their role in keeping the area tidy. This not only improves workflow but also contributes to a healthier, more comfortable working environment, ultimately enhancing overall job performance and employee retention.

Lean Management Principles to Enhance Workplace Layout

Implementing Lean Management principles can significantly enhance your workspace layout and overall productivity. The core of this approach lies in the 5S training methodology, which promotes a disciplined and organized environment. This involves sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke) work areas. By adhering to these practices, you create a more efficient workplace organization.

Process standardization is another key element of lean management, ensuring that tasks are completed consistently and with minimal waste. This can be achieved through clear documentation, standardized procedures, and regular training sessions. A well-organized and streamlined workspace not only improves employee comfort but also encourages a culture of continuous improvement, driving overall business success.

The Role of Continuous Improvement in Creating an Ergonomic Environment

Creating an ergonomic workspace is an ongoing process that heavily relies on continuous improvement. Implementing 5S training and lean management principles can significantly enhance workplace organization. This involves sorting, setting in order, shining (cleaning), standardizing processes, and sustaining these practices through regular reviews. By adopting a structured approach like the 5S method, organizations can ensure every element in the workspace is optimized for efficiency and comfort.

Process standardization plays a pivotal role here, as it ensures that everyone follows established procedures for tasks, reducing variations that may cause strain on employees’ bodies. Regular assessments and adjustments based on feedback further refine the ergonomic design, making it adaptable to changing needs and technologies. This iterative process guarantees that the workspace remains an ideal environment for productivity while minimizing physical stress.

Process Standardization: A Key Strategy for Sustainable Workspace Ergonomics

In today’s dynamic work environment, Process Standardization is a key strategy for achieving and maintaining sustainable ergonomic workspace design. Implementing 5S training, rooted in lean management principles, can dramatically improve workplace organization. This involves sorting, setting in order, shining (cleaning), standardizing, and sustaining—a continuous improvement process that ensures every aspect of the workspace is optimized for efficiency and comfort.

By adopting these practices, organizations can minimize distractions, reduce physical strain on employees, and foster a culture of productivity. Regular 5S assessments and ongoing process standardization enable teams to identify and eliminate inefficiencies, ensuring that ergonomic principles are seamlessly integrated into daily operations. This not only enhances employee well-being but also contributes to the overall success and competitiveness of the organization.

Ergonomic workspace design is not just a trend but an essential strategy for fostering productivity, employee well-being, and overall job satisfaction. By implementing principles from 5S training, lean management, and continuous improvement, organizations can create sustainable environments that meet the physical needs of their workforce. Process standardization ensures these practices remain consistent and effective over time, ultimately revolutionizing workplace organization and enhancing the quality of work life for all employees.