Lean Manufacturing and 5S Training: Optimizing Productivity through Waste Elimination and Standardization

Lean manufacturing, rooted in Toyota's production system, focuses on eliminating waste and maximizing efficiency. The cornerstone of this approach is 5S training, a structured framework comprising Sort, Set in Order, Shine (clean), Standardize, and Sustain. This methodology promotes continuous improvement by organizing workspaces, standardizing processes, and encouraging constant evaluation. Through 5S continuous improvement initiatives, lean management achieves reduced errors, increased productivity, enhanced workplace organization, and improved overall operational efficiency while fostering a culture of excellence among employees.

“Lean manufacturing is a transformative production philosophy that has taken industries by storm. This article delves into the core principles and methodologies behind this paradigm shift, offering a comprehensive guide to optimizing operations.

From understanding the foundational 5S training methodology to exploring lean management’s resource optimization capabilities, each section uncovers crucial aspects. We’ll examine how workplace organization acts as a catalyst for continuous improvement and delve into the cycle of efficiency that is 5S continuous improvement. Finally, we’ll highlight process standardization as the linchpin for maintaining lean principles.”

- Understanding Lean Manufacturing: A Paradigm Shift in Production

- The Foundation of Lean: The 5S Training Methodology

- Lean Management: Optimizing Resources and Streamlining Workflows

- Workplace Organization: Creating an Environment for Continuous Improvement

- 5S Continuous Improvement: A Cycle of Evolution and Efficiency

- Process Standardization: The Key to Sustaining Lean Principles

Understanding Lean Manufacturing: A Paradigm Shift in Production

Lean manufacturing represents a significant paradigm shift in production, focusing on eliminating waste and maximizing efficiency. It’s not just about streamlining processes; it’s a holistic approach that encompasses every aspect of production, from raw material to finished product. This philosophy originated in Japan with Toyota’s production system, known for its precision and minimalism. Today, lean management principles are adopted worldwide, serving as a beacon for optimal workplace organization.

At the heart of lean manufacturing lies the 5S training framework: Sort, Set in Order, Shine (clean), Standardize, and Sustain. This continuous improvement methodology encourages teams to constantly evaluate their work areas and processes, discarding what’s unnecessary, organizing what’s essential, and standardizing best practices. By fostering a culture of process standardization, lean manufacturing aims to reduce errors, increase productivity, and enhance overall workplace organization.

The Foundation of Lean: The 5S Training Methodology

The foundation of Lean manufacturing lies in a powerful methodology known as 5S training. This systematic approach to workplace organization and continuous improvement is at the core of Lean management principles. The 5S framework stands for Sort, Set in Order, Shine (or Clean), Standardize, and Sustain, each representing a critical step in streamlining processes and eliminating waste.

By implementing 5S training, organizations can transform their workplaces into highly efficient systems. It involves sorting through unnecessary items, setting up a logical workspace layout, maintaining cleanliness and order, establishing standardized procedures, and fostering a culture of continuous improvement. This method not only enhances productivity but also ensures process standardization, enabling teams to work more effectively and efficiently.

Lean Management: Optimizing Resources and Streamlining Workflows

Lean management is a philosophy that focuses on optimizing resources and streamlining workflows to enhance efficiency and productivity. At its core, it advocates for the elimination of waste, which can take many forms in a manufacturing setting, from overproduction and waiting times to unnecessary movements and defects. This approach emphasizes the importance of a well-organized workplace, achieved through practices like 5S training, which involves sorting, setting in order, shining (cleaning), standardizing, and sustaining these improvements.

By implementing lean management principles, businesses can achieve better process standardization, ensuring that operations are consistent, predictable, and efficient. This includes continuous improvement initiatives driven by employee participation, where teams identify and address inefficiencies in real time. Such practices lead to a more agile and responsive organization, capable of quickly adapting to changing market demands while minimizing costs and maximizing output.

Workplace Organization: Creating an Environment for Continuous Improvement

Workplace Organization is a cornerstone of Lean manufacturing, fostering an environment conducive to continuous improvement. The 5S training methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—serves as a powerful tool for achieving this goal. By implementing 5S continuous improvement practices, lean management ensures that every workspace is organized, efficient, and designed to eliminate waste. Process standardization becomes second nature when workers are trained to maintain a clean and orderly environment, enabling them to quickly identify inefficiencies and make data-driven adjustments.

A well-organized workplace not only enhances productivity but also encourages collaboration and innovation. When each employee has a designated space that is easily accessible and logical, it reduces the time spent searching for tools or materials, allowing for more focus on value-added activities. This, in turn, creates an atmosphere where continuous improvement becomes a shared responsibility, as everyone plays a vital role in maintaining and enhancing the efficiency of their work environment.

5S Continuous Improvement: A Cycle of Evolution and Efficiency

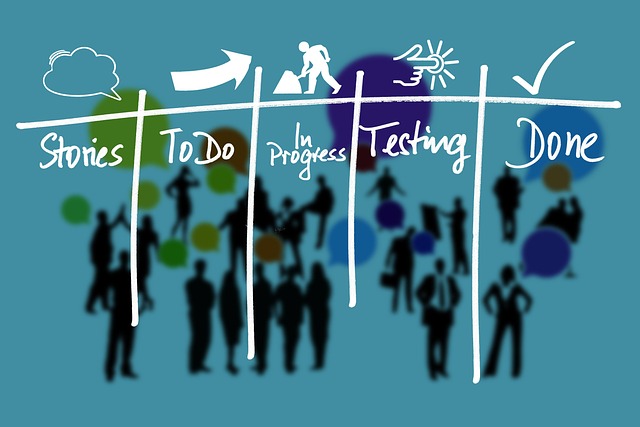

The 5S method is a powerful tool within lean manufacturing, focusing on workplace organization and continuous improvement. It involves five key disciplines: Sort, Set in Order, Shine (or Clean), Standardize, and Sustain. This cycle ensures that the workspace remains organized, efficient, and safe by eliminating waste and streamlining processes.

5S training empowers employees to take an active role in their work environment’s evolution. By consistently applying these principles, teams can achieve remarkable process standardization and lean management. Regular 5S continuous improvement initiatives foster a culture of excellence, where every step is measured, and adjustments are made to optimize productivity and quality.

Process Standardization: The Key to Sustaining Lean Principles

Process Standardization is a cornerstone of Lean manufacturing principles, ensuring consistent and efficient operations. By implementing 5S training, organizations can systematically organize their workplaces, eliminating waste and streamlining workflows. This involves sorting items, setting in order, shining a light on improvement areas, standardizing procedures, and sustaining continuous improvement.

Lean management advocates for clear process standardization to foster workplace organization. Standardized processes provide a foundation for measurable efficiency, enabling employees to focus on value-adding activities. Regular reviews and adjustments ensure that these standards remain relevant and effective in an ever-evolving business landscape.

Lean manufacturing is a transformative approach that prioritizes efficiency and continuous improvement. By implementing principles like 5S training for foundational workplace organization, optimizing resource allocation through lean management, and standardizing processes, businesses can create seamless workflows. This not only enhances productivity but also fosters a culture of evolution and adaptability. Embracing 5S continuous improvement ensures ongoing refinement, making it a powerful tool for staying competitive in today’s market.