The Business Efficiency Model leverages powerful methodologies like 5S training and lean management to transform workplaces. By adopting a systematic approach, organizations question and streamline every element for maximum efficiency. Through 5S principles (sort, set in order, shine, standardize, sustain), they create tidy, structured environments that boost productivity and reduce waste. Process standardization, involving workflow documentation and refinement, eliminates bottlenecks and fosters continuous improvement. Regular 5S training sessions maintain organized workspaces, enhance safety, and promote a culture where every employee contributes to optimizing business processes.

In today’s competitive business landscape, achieving peak efficiency is not just advantageous but essential. This article delves into a comprehensive framework known as the Business Efficiency Model, offering practical strategies for optimization. We explore key components like 5S training for workplace organization and Lean Management techniques to streamline processes. By implementing these principles, businesses can enhance productivity, reduce waste, and ensure process standardization, driving continuous improvement in every aspect of their operations.

- Understanding the Business Efficiency Model: A Comprehensive Framework

- Implementing 5S Training for Optimal Workplace Organization

- Lean Management Techniques: Streamlining Processes for Continuous Improvement

- Process Standardization: The Key to Sustaining Efficient Operations

Understanding the Business Efficiency Model: A Comprehensive Framework

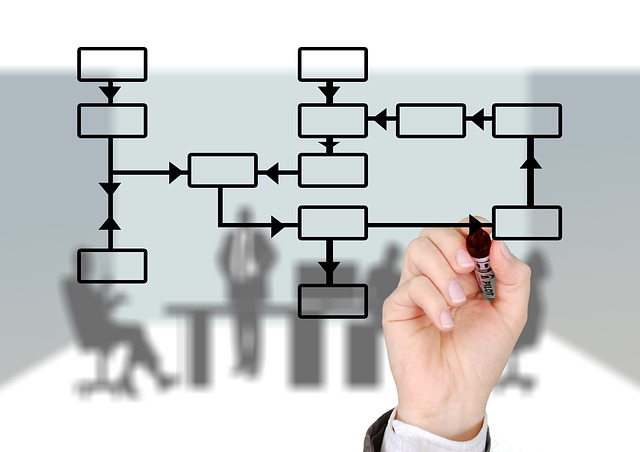

The Business Efficiency Model is a comprehensive framework designed to optimize operations and enhance productivity. At its core, it leverages powerful methodologies like 5S training and lean management to transform workplaces. This involves a systematic approach to workplace organization, where every element is questioned and streamlined for maximum effectiveness. By implementing 5S continuous improvement principles—sort, set in order, shine (clean), standardize, sustain—organizations can create an environment that promotes efficiency and reduces waste.

Process standardization is another critical aspect, ensuring that tasks are executed consistently and effectively across the board. This means documenting, analyzing, and refining workflows to eliminate bottlenecks and inefficiencies. When integrated into daily practices, these strategies not only improve productivity but also foster a culture of continuous improvement, where every employee plays a role in optimizing business processes.

Implementing 5S Training for Optimal Workplace Organization

Implementing 5S Training is a powerful strategy for businesses aiming to achieve optimal workplace organization and efficiency. This proven method, rooted in lean management principles, focuses on creating a tidy, structured, and standardized work environment. By teaching employees the 5S principles—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—organizations can dramatically improve productivity and reduce waste.

5S continuous improvement encourages a culture of process standardization where every employee understands their role in maintaining an organized workspace. This not only streamlines operations but also fosters a safer, more productive atmosphere. Through regular 5S training sessions, companies can ensure that workplace organization remains a top priority, leading to sustained efficiency gains over time.

Lean Management Techniques: Streamlining Processes for Continuous Improvement

Lean Management Techniques, rooted in the principles of lean manufacturing, focus on streamlining processes to eliminate waste and enhance efficiency. One key component is 5S training, a systematic approach that encourages workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining these practices. This method promotes a culture of continuous improvement where every employee plays a role in identifying and eliminating non-value-added steps in their workflow.

By implementing 5S and lean management principles, businesses can achieve process standardization, leading to increased productivity and improved quality control. The structured environment created by these techniques enables employees to work more efficiently, reduces errors, and fosters an atmosphere where innovation thrives. This continuous improvement mindset ensures that the business remains competitive in a dynamic market.

Process Standardization: The Key to Sustaining Efficient Operations

Process Standardization is a cornerstone in sustaining efficient business operations, underpinning principles of lean management and 5S training. By establishing clear, consistent processes across departments and roles, organizations minimize waste, reduce errors, and optimize productivity. This involves standardizing tasks, methods, and procedures to ensure every employee understands and follows the same approach.

Workplace organization is significantly enhanced through process standardization, allowing for better resource allocation, improved communication, and a culture of continuous improvement driven by the 5S continuous improvement methodology. It fosters a disciplined environment where employees are equipped with the knowledge and skills to perform their duties effectively, ultimately contributing to overall business success.

The business efficiency model, encompassing 5S training, lean management techniques, and process standardization, offers a comprehensive framework for optimizing workplace organization. By implementing these strategies, businesses can achieve significant improvements in operational efficiency, reduce waste, and foster a culture of continuous improvement. Integrating 5S principles for workspace organization, leveraging lean methods to streamline processes, and standardizing procedures ensures sustained efficiency, ultimately driving business success in today’s competitive market.