5S training, a core lean management tool, transforms workplaces through sorting, setting in order, cleaning, standardizing, and continually improving. This method enhances efficiency, quality, and productivity by aligning operations with customer value creation, fostering a culture of continuous improvement and workplace organization. Regular 5S practices lead to process standardization, reducing waste, and driving organizational success by empowering employees to identify and eliminate inefficiencies.

“Unleash productivity and efficiency in your workplace with the powerful Lean philosophy. This article explores the transformative potential of Lean management principles, focusing on the core concepts of 5S training. From understanding foundational principles to implementing systematic workplace organization, we delve into the benefits of process standardization. Discover how continuous improvement is achieved through 5S methodologies, empowering your team to excel in a streamlined environment. Optimize workflows and watch your business thrive.”

- Understanding Lean Management Principles

- The Core Components of 5S Training

- Workplace Organization: A Systematic Approach

- Continuous Improvement Through 5S

- Standardizing Processes for Efficient Workflows

Understanding Lean Management Principles

At its core, Lean Management is a philosophy that focuses on maximizing value while minimizing waste within an organization. This approach emphasizes creating more efficient processes, eliminating unnecessary steps, and fostering a culture of continuous improvement. The foundation of Lean lies in understanding and prioritizing what truly adds value from the customer’s perspective.

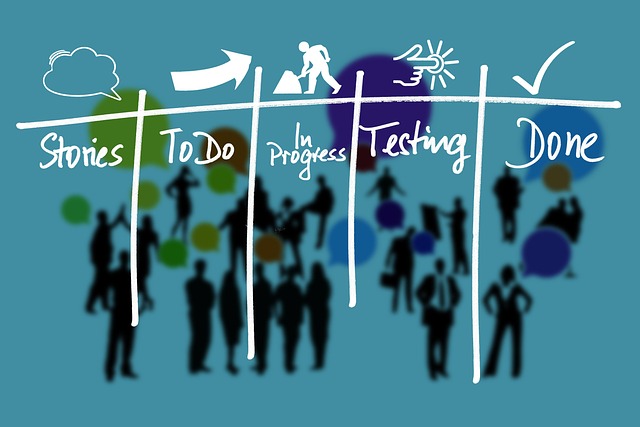

The 5S training method is a popular tool within this framework, aiming to organize workplaces by sorting (Seiri), setting things in order (Seiton), shining (Seiso), standardizing (Seiketsu), and continually improving (Shitsuke). This systematic approach to workplace organization and process standardization ensures that every aspect of operations contributes to the overall efficiency, quality, and productivity of the business.

The Core Components of 5S Training

The core components of 5S training are fundamental to implementing a lean management philosophy in any workplace. This structured approach to organization and process improvement has its roots in Japanese manufacturing practices, emphasizing efficiency, quality, and safety. The ‘5S’ acronym itself is a mnemonic for five disciplined steps: Sort (removing waste and clutter), Set in Order (arranging items logically), Shine (maintaining cleanliness), Standardize (establishing consistent procedures), and Sustain (continuing the cycle of continuous improvement).

Effective 5S training goes beyond mere instruction. It involves empowering employees to take ownership of their workspace and processes, fostering a culture of involvement and accountability. By integrating these principles into daily routines, organizations can achieve remarkable levels of workplace organization and efficiency. This, in turn, drives process standardization, enabling smoother operations, reduced waste, and improved overall productivity, ultimately contributing to the ongoing journey of lean management.

Workplace Organization: A Systematic Approach

A lean workplace philosophy prioritizes efficiency and productivity through a systematic approach to workplace organization. This involves implementing 5S training, a methodology that stands for Sort, Set in Order, Shine (clean), Standardize, and Sustain. By teaching employees to minimize clutter and optimize workspace layout, 5S fosters an environment conducive to improved workflow and reduced waste.

Lean management intertwines with process standardization, ensuring every task is executed consistently and efficiently. This involves documenting and streamlining work processes, allowing for continuous improvement over time. Such a structured approach not only enhances overall workplace organization but also empowers employees to identify and eliminate inefficiencies, ultimately driving organizational success.

Continuous Improvement Through 5S

Standardizing Processes for Efficient Workflows

In a lean workplace philosophy, standardizing processes is paramount for achieving efficient workflows. This involves implementing 5S training, a system that promotes workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining. By adopting lean management principles, organizations can ensure every step of their operations is clearly defined, streamlining tasks and eliminating waste.

Process standardization facilitates continuous improvement, where each step is regularly reviewed and optimized. This not only enhances productivity but also ensures consistency in quality. As a result, teams are empowered to work more effectively, focusing on value-added activities while minimizing non-value-added efforts, ultimately driving overall organizational success.

By implementing lean management principles and focusing on effective 5S training, organizations can achieve exceptional workplace efficiency. This article has explored the core components of 5S, from systematic workplace organization to continuous improvement through standardized processes. Adopting these practices not only enhances productivity but also fosters a culture of quality and innovation. By streamlining workflows and eliminating waste, businesses can create an environment that drives success in today’s competitive market, ensuring sustained growth and improved customer satisfaction.