“Discover the transformative power of Lean workplace philosophy in today’s competitive business landscape. This comprehensive guide delves into the core principles of Lean management and its profound impact on organizational success. Explore proven strategies like 5S training for unparalleled efficiency and process standardization techniques to streamline workflows. Learn how integrating these methodologies fosters continuous improvement, enhancing productivity and workplace organization. Optimize your operations with practical insights tailored for long-term success.”

- Understanding the Lean Workplace Philosophy: A Comprehensive Overview

- The Core Principles of Lean Management and Its Impact on Organization

- Unlocking Efficiency: Implementing 5S Training for Continuous Improvement

- Process Standardization: Streamlining Workflows for Optimal Productivity

- Sustaining Success: Integrating 5S Methodology into Everyday Practice

Understanding the Lean Workplace Philosophy: A Comprehensive Overview

The Lean Workplace Philosophy is a systematic approach to optimizing workplace operations and enhancing overall efficiency. It originated from Toyota’s manufacturing processes, known as the Toyota Production System (TPS), and has since been adapted for various industries worldwide. This philosophy centers on eliminating waste, improving workflow, and empowering employees to drive continuous improvement. At its core, Lean management promotes the idea that organizations should focus on creating value for customers while minimizing non-value-added activities.

A key component of this philosophy is 5S training, a methodology that includes sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke). This system transforms workplaces into organized, efficient environments where every element has its place. By implementing process standardization and continuous improvement practices, organizations can streamline workflows, reduce errors, and increase productivity. Lean workplace organization ensures that resources are utilized effectively, leading to improved quality, faster lead times, and increased customer satisfaction.

The Core Principles of Lean Management and Its Impact on Organization

Unlocking Efficiency: Implementing 5S Training for Continuous Improvement

Unlocking Efficiency: Implementing 5S Training for Continuous Improvement

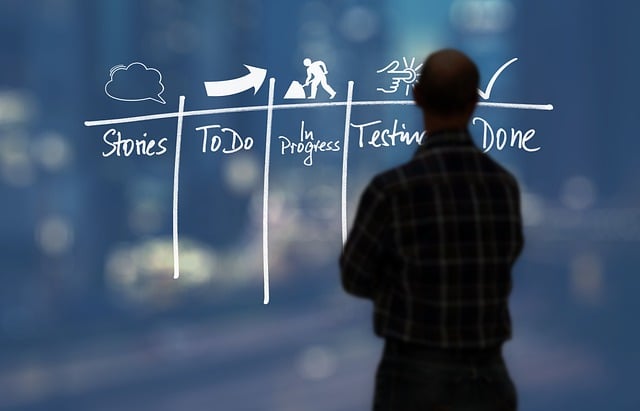

In the realm of lean management, workplace organization is a powerful tool for achieving efficiency and enhancing productivity. A key strategy within this framework is 5S training, a methodical approach that transforms cluttered workspaces into streamlined operations. By focusing on Sort, Set in Order, Shine (Clean), Standardize, and Sustain, organizations can cultivate a culture of continuous improvement. This process begins with sorting through unnecessary items, organizing tools and equipment for easy accessibility, and shining (cleaning) to maintain an orderly environment. Process standardization is then achieved by establishing clear procedures and documenting best practices, ensuring consistency and reducing waste.

5S continuous improvement empowers employees to take ownership of their work areas, fostering a sense of responsibility and pride. Regular training sessions reinforce these principles, allowing teams to identify inefficiencies and implement solutions tailored to their unique needs. As a result, workflows become more seamless, decision-making is accelerated, and overall productivity skyrockets. This lean management technique is a game-changer for any organization seeking to optimize its processes and stay ahead in today’s competitive market.

Process Standardization: Streamlining Workflows for Optimal Productivity

Process Standardization is a cornerstone of the lean workplace philosophy, focusing on streamlining workflows to maximize productivity and efficiency. At its core, this involves implementing 5S training – a methodology that emphasizes sorting, setting in order, shining (cleaning), standardizing, and sustaining. By systematically organizing the workspace and establishing clear standards for every process, employees can work more effectively and with greater consistency.

This approach goes beyond mere workplace organization; it drives continuous improvement through regular reviews and adjustments to ensure processes remain optimized over time. Lean management principles encourage teams to identify and eliminate waste, such as unnecessary steps or downtime, which directly contributes to improved productivity and better overall performance.

Sustaining Success: Integrating 5S Methodology into Everyday Practice

The Lean workplace philosophy, centred around concepts like 5S training and process standardization, offers a transformative path to enhanced efficiency and productivity. By adopting lean management principles, organizations can streamline workflows, eliminate waste, and foster an environment of continuous improvement. Integrating 5S methodologies into daily practices ensures sustained success, allowing businesses to stay competitive in today’s fast-paced market. This strategic approach not only optimizes resource utilization but also improves overall workplace organization, ultimately driving organizational growth and excellence.