The 5S training methodology, rooted in lean management, transforms workplaces through sorting, organizing, cleaning, standardizing, and maintaining. By encouraging employee participation, it drives process standardization, eliminates waste, enhances productivity, and fosters continuous improvement, ultimately boosting morale in a structured environment. This approach is key to achieving efficient, safe, and well-organized spaces, leading to long-term organizational success.

In today’s competitive business landscape, efficient and organized workspaces are key to unlocking productivity. Discover the transformative power of the 5S Training Methodology—a proven approach rooted in lean management principles. This article delves into strategies like understanding 5S, leveraging Lean Management, implementing organization techniques, harnessing continuous improvement, and standardizing processes for long-term success. Optimize your workspace and witness a surge in efficiency with these powerful tools.

- Understanding the 5S Training Methodology

- Lean Management Principles for Efficient Workspace

- Unlocking Productivity: Workplace Organization Techniques

- Continuous Improvement: The 5S Framework's Power

- Standardizing Processes for Long-Term Success

Understanding the 5S Training Methodology

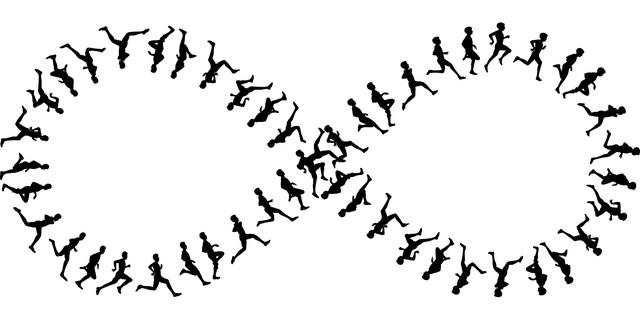

The 5S Training Methodology is a powerful tool in the realm of lean management and workplace organization. This systematic approach, rooted in Japanese production principles, aims to transform spaces into efficient, safe, and organized environments through five key steps: Sort, Set in Order, Shine (or Clean), Standardize, and Sustain. Each stage builds upon the previous one, fostering a culture of continuous improvement. By implementing 5S, businesses can achieve process standardization, eliminate waste, and enhance productivity.

This training method encourages employees to actively participate in the transformation process. It starts with sorting through items and keeping only what is essential for daily tasks, followed by organizing these items for quick access. Regular cleaning and maintenance ensure a bright and safe workspace. Standardization involves establishing consistent procedures, while sustainability focuses on maintaining the organized environment over time.

Lean Management Principles for Efficient Workspace

Implementing Lean Management principles is a game-changer for optimizing your workplace organization. The core of this approach lies in the 5S training methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain. This system encourages employees to regularly examine their workspace, eliminating unnecessary items and streamlining processes. By ‘sorting’ through clutter and assigning specific locations for tools and materials (‘set in order’), teams can enhance productivity and reduce time wasted on searching.

The ‘shine’ step promotes a culture of cleanliness and order, ensuring an efficient, safe, and visually appealing environment. Moreover, ‘standardization’ involves creating and adhering to consistent processes, which leads to process standardization. This continuous improvement mindset, driven by the 5S framework, fosters a workplace where every element serves a purpose, ultimately boosting overall productivity and employee morale.

Unlocking Productivity: Workplace Organization Techniques

Unlocking Productivity: Workplace Organization Techniques

Workplace organization goes beyond aesthetics; it’s a powerful tool for boosting productivity and employee morale. Core techniques like 5S training—a methodology rooted in lean management—offer a structured approach to streamlining operations. By teaching employees to organize, clean, and standardize their work areas, companies can eliminate waste and create efficient workflows. This, in turn, enhances focus and fosters a culture of continuous improvement.

Implementing 5S principles encourages regular audits and ongoing process standardization, ensuring that the workplace remains optimized for productivity. This systematic approach not only improves individual tasks but also contributes to the overall success of the organization by promoting a culture where every employee takes pride in their role and the quality of their work environment.

Continuous Improvement: The 5S Framework's Power

In the realm of workplace organization, continuous improvement is a cornerstone for achieving efficiency and productivity. The 5S Framework, rooted in lean management principles, offers a powerful methodology to transform work environments. This system emphasizes the importance of sorting, setting in order, shining (cleaning), standardizing, and sustaining these practices for optimal results.

By implementing 5S training, organizations can streamline processes, reduce waste, and enhance overall workplace organization. Process standardization ensures that tasks are executed consistently, minimizing errors and maximizing productivity. This continuous improvement approach fosters a culture of excellence where every employee plays a vital role in refining workflows, ultimately driving business success and creating a more efficient, effective work environment.

Standardizing Processes for Long-Term Success

In the quest for a well-organized and efficient workplace, standardizing processes is paramount for long-term success. This involves implementing structured methods that ensure every task is executed consistently, promoting productivity and quality. The lean management approach, with its roots in 5S training, offers a powerful framework for process standardization. By teaching employees to sort, set in order, shine (clean), standardize, and sustain these practices, the workplace becomes a more streamlined environment.

5S continuous improvement encourages regular assessments and adjustments, fostering a culture of constant refinement. This not only enhances operational efficiency but also contributes to employee engagement by empowering them to take ownership of their roles. Through process standardization, organizations can minimize waste, reduce errors, and create a safer, more engaging work environment, ultimately driving long-term success.

By implementing the 5S training methodology and embracing lean management principles, organizations can significantly enhance their workplace organization. The techniques outlined, such as unlocking productivity through efficient systems and fostering continuous improvement with the 5S framework, offer proven paths to optimization. Standardizing processes ensures long-term success by streamlining workflows, minimizing waste, and maximizing employee engagement. Adopting these strategies not only improves operational efficiency but also creates a more productive and fulfilling work environment.