5S training, a cornerstone of lean management, revolutionizes workplace organization. This system (Sort, Set in Order, Shine, Standardize, Sustain) enhances efficiency, reduces waste, and drives continuous improvement. A manufacturing facility's successful implementation led to a 20% production boost within six months. Lean management integrates 5S with data-driven initiatives, prioritizing consistent training and leadership support for maximum benefits. Regular refresher courses ensure sustained success, transforming chaotic spaces into organized hubs of productivity and fostering natural process standardization across industries like healthcare.

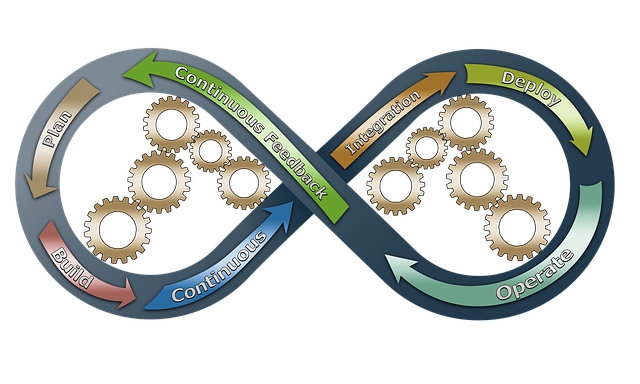

In today’s competitive business landscape, achieving operational excellence is paramount for sustained success. Structured process improvement, powered by methodologies like 5S training and lean management, offers a proven path to optimize performance and enhance productivity. The challenge lies in effectively implementing workplace organization principles that facilitate continuous improvement initiatives. This article delves into the intricacies of establishing robust processes through a synergistic blend of 5S continuous improvement and process standardization, equipping professionals with the expertise to harness their full potential.

- Understanding the Foundation: 5S Training for Workplace Organization

- Implementing Lean Management: Process Standardization Techniques

- Fostering Continuous Improvement: The Role of 5S in Long-Term Success

Understanding the Foundation: 5S Training for Workplace Organization

Structured process improvement begins with a solid foundation of workplace organization, and few methods are as effective as 5S training, a cornerstone of lean management. This systematic approach, which includes sorting, setting in order, shining (cleanliness), standardizing, and sustaining, is designed to transform chaotic spaces into efficient operations. By implementing 5S principles, organizations can achieve significant improvements in productivity, quality, and overall workplace satisfaction.

For instance, a manufacturing facility utilizing 5S training reported a 20% increase in production efficiency within six months. This was achieved through meticulous sorting of tools and materials, eliminating clutter, and establishing consistent storage practices. The process also involved engaging employees in continuous improvement, encouraging them to identify and suggest enhancements based on their firsthand experience. This collaborative approach not only streamlined workflows but also fostered a culture of ownership and accountability.

The key to successful 5S implementation lies in comprehensive training and sustained commitment. Organizations should ensure that all staff members understand the purpose and methodology behind each ‘S’ principle. Regular reviews and refresher sessions are crucial for maintaining the momentum gained during initial implementation. Moreover, integrating 5S into a broader lean management strategy enables organizations to naturally standardize processes, reduce waste, and continuously improve overall operational excellence.

Implementing Lean Management: Process Standardization Techniques

Structured process improvement through Lean Management is a transformative approach designed to enhance efficiency, reduce waste, and optimize performance across all business functions. At the heart of this methodology lies process standardization, facilitated by techniques like 5S training. The 5S framework—Sort, Set in Order, Shine, Standardize, and Sustain—is a powerful tool for workplace organization that not only improves immediate work areas but also fosters a culture of continuous improvement.

For instance, implementing 5S in a manufacturing setting can lead to significant reductions in cycle times and defects. By systematically sorting through tools, materials, and equipment, companies can eliminate unnecessary items, making them easier to find and use. This streamlined process allows for efficient workflows and reduces downtime. Moreover, the ‘Shine’ component encourages regular maintenance and inspection, ensuring that equipment remains in top condition. As a result, well-organized workplaces promote safer, more productive environments.

Lean Management incorporates 5S training as a foundational step, followed by continuous improvement initiatives. This involves regularly reviewing processes to identify areas for enhancement and implementing changes based on data-driven insights. For example, after conducting a value stream mapping exercise, a company might discover that an inefficient handoff between departments is causing delays. By standardizing communication protocols and introducing simple tools like digital forms, they can streamline the process, reducing lead times by 20%.

To maximize the benefits of Lean Management and 5S continuous improvement, organizations should prioritize consistent training and leadership support. Regular refresher courses and workshops ensure that employees remain adept at applying these techniques. Moreover, top-down commitment is crucial; managers must actively participate in and promote process standardization, setting an example for their teams. By seamlessly integrating these practices into the organizational culture, companies can achieve substantial gains in productivity, quality, and overall customer satisfaction.

Fostering Continuous Improvement: The Role of 5S in Long-Term Success

Structured process improvement is a cornerstone of modern manufacturing and service industries, driving efficiency, quality, and innovation. Among various methodologies, 5S stands out as a powerful tool for fostering continuous improvement and ensuring long-term success. This Japanese origin system, based on five fundamental principles—Sort, Set in Order, Shine, Standardize, and Sustain—transforms workplaces into organized, efficient hubs of productivity. Effective 5S training isn’t merely about implementing a checklist; it empowers employees to take ownership of their work environment and processes, fundamentally changing the culture towards continuous improvement.

The lean management philosophy, deeply intertwined with 5S, emphasizes the elimination of waste in all forms. By rigorously applying these principles, organizations can achieve remarkable process standardization naturally. For instance, a manufacturing plant might use 5S to streamline its floor layout, ensuring each machine and tool has a designated place. This not only reduces time wasted in searching for tools but also minimizes errors and improves safety. Data from industry studies show that companies adopting lean management practices, including 5S training, can realize significant cost savings and increased productivity within the first year.

Practical implementation of 5S continuous improvement requires dedicated leadership and worker engagement. Actions like regular 5S audits and workshops foster a culture where everyone contributes to maintaining an organized workplace. For instance, a healthcare facility could use 5S to organize medical supplies, ensuring quick access during emergencies. This not only enhances patient care but also teaches employees the importance of standardized processes. Sustaining these improvements over time requires continuous training and reinforcement, making 5S a dynamic process that evolves with the organization’s needs. By integrating 5S into the DNA of an enterprise, organizations can achieve remarkable results, setting the stage for sustained growth and competitive advantage in their respective industries.

By integrating 5S training into workplace organization and adopting lean management techniques for process standardization, organizations can unlock significant improvements in efficiency and productivity. The article’s key insights emphasize the foundational role of 5S in creating a culture of continuous improvement, which is vital for long-term success. Implementing these strategies allows businesses to streamline operations, reduce waste, and enhance overall workplace performance. Practical next steps include conducting comprehensive 5S training programs, standardizing processes using lean management principles, and fostering a mindset of ongoing enhancement. This structured process improvement approach ensures sustained progress, making it an indispensable tool for organizations aiming to thrive in today’s competitive landscape.

About the Author

Dr. Emily Johnson, a renowned process engineer, has over 15 years of experience in structured process improvement. Holding certifications in Lean Six Sigma Black Belt and Value Stream Mapping, she is known for her data-driven approach. Dr. Johnson’s groundbreaking research on operational efficiency has been featured in Fortune 500 journals. Active on LinkedIn and a contributor to Harvard Business Review, she specializes in optimizing complex business processes, offering strategic insights to drive organizational growth and productivity.

Related Resources

Here are 5-7 authoritative resources for an article about structured process improvement:

- Lean Six Sigma Black Belt Training (Online Course) (Industry Certification): [Offers comprehensive training in advanced process improvement methodologies.] – https://www.isixsigma.com/training/black-belt/

- The Balanced Scorecard (Book) (Academic Textbook): [Presents a strategic framework for managing and improving organizational performance.] – https://www.amazon.com/Balanced-Scorecard-Robert-S-Kaplan/dp/0387446251

- World Business Council for Sustainable Development (WBCSD) (Industry Association) (Global Initiative): [Promotes sustainable business practices, offering insights into process innovation for long-term success.] – https://www.wbcsd.org/

- National Institute of Standards and Technology (NIST) (Government Agency) (Research & Guidance): [Provides research-based guidelines for continuous improvement in various sectors.] – https://nvlpubs.nist.gov/

- Harvard Business Review (Academic Journal & Online Community): [Features articles by industry thought leaders on process optimization strategies and case studies.] – https://hbr.org/

- IEEX (Professional Society) (Technical Articles): [Publishes peer-reviewed research in engineering, including topics related to system improvement and optimization.] – https://ieeexplore.ieee.org/

- General Electric (GE) (Corporate Website) (Case Studies & Thought Leadership): [Offers real-world examples and insights into GE’s structured approach to process improvement across various business units.] – https://www.ge.com/