In today's digital age, 5S training, a lean management approach, is crucial for enhancing workplace safety and efficiency. By focusing on organizing spaces, standardizing processes, and continually improving workflows (Sort, Set in Order, Shine, Standardize, Sustain), this methodology empowers employees to create safer, more organized work environments. Process standardization reduces hazards, improves visibility, fosters collaboration, and drives continuous improvement, ultimately leading to increased productivity and a hazard-free workspace.

In today’s dynamic work environment, prioritizing workplace safety is paramount. This comprehensive guide explores proven initiatives that transform workplaces into safer, more efficient operations. From the foundational principles of 5S training to advanced techniques like lean management and process standardization, each section delves into essential strategies. Learn how workplace organization reduces hazards and continuous improvement ensures a culture of safety that benefits every employee.

- Understanding the Foundation: 5S Training Essentials

- Lean Management: Streamlining Workflows for Safety

- Workplace Organization: A Key to Hazard Mitigation

- Continuous Improvement: 5S Beyond the Basics

- Process Standardization: Ensuring Consistency and Security

- Fostering a Culture of Safety Through Initiative Adoption

Understanding the Foundation: 5S Training Essentials

In today’s digital era, workplace safety initiatives are more crucial than ever. One proven approach to enhancing safety and efficiency is through 5S training, a cornerstone of lean management. This methodology focuses on organizing work areas, standardizing processes, and continually improving workflow, thereby reducing risks and increasing productivity. The “5S” stands for Sort (remove unnecessary items), Set in Order (arrange tools and equipment logically), Shine (clean and maintain the workspace), Standardize (establish consistent practices), and Sustain (cultivate a culture of 5S).

Effective 5S training involves teaching employees these principles not just as tasks, but as a mindset. By implementing process standardization and workplace organization, teams can navigate their environment more safely and efficiently. This continuous improvement approach ensures that safety measures are not one-time fixes but integral parts of the company culture, fostering an environment where everyone takes pride in maintaining a safe, organized workspace.

Lean Management: Streamlining Workflows for Safety

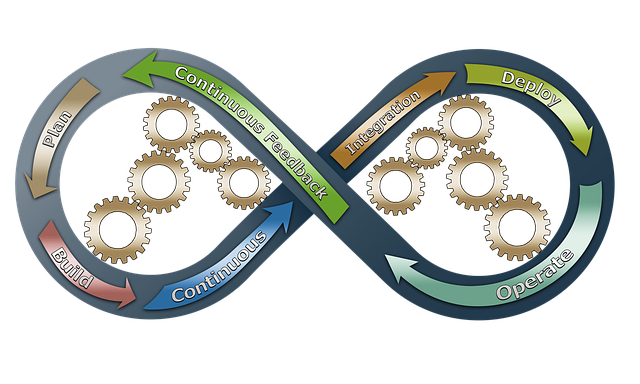

Implementing Lean Management principles is a powerful strategy to enhance workplace safety through streamlined workflows. This approach, rooted in the 5S training methodology, promotes an organized and efficient work environment. By encouraging employees to sort, set in order, shine (clean), standardize, and sustain these practices, potential hazards are eliminated, and safe operational procedures become second nature.

Lean Management focuses on process standardization, ensuring that tasks are completed efficiently with minimal waste. This systematic organization reduces the risk of accidents caused by disarray or unfamiliar surroundings. Regular 5S continuous improvement initiatives foster a culture where everyone takes responsibility for maintaining a safe, well-organized workplace, ultimately contributing to a more productive and hazard-free work environment.

Workplace Organization: A Key to Hazard Mitigation

Workplace Organization plays a pivotal role in mitigating potential hazards and fostering a safer environment for employees. Implementing robust 5S training methodologies is a powerful strategy to achieve this. The 5S method, comprising Sort, Set in Order, Shine (Clean), Standardize, and Sustain, offers a structured approach to workplace organization. Through sorting and discarding unnecessary items, setting up processes for maintaining order, regular cleaning, establishing standards, and promoting continuous improvement, organizations can significantly reduce trip hazards, improve visibility, and enhance overall safety.

Integrating lean management principles further reinforces these efforts. Process standardization ensures that tasks are performed consistently, minimizing errors and accidents. By streamlining workflows, eliminating waste, and optimizing processes, workplace organization becomes more efficient, allowing employees to focus on their roles without distractions, ultimately contributing to a safer, more productive work environment.

Continuous Improvement: 5S Beyond the Basics

In today’s competitive business landscape, continuous improvement is no longer an option but a necessity. One powerful framework that has been widely adopted in various industries for driving this culture of excellence is 5S—a lean management principle focusing on workplace organization and process standardization. Beyond the basics of sorting, setting in order, shining (cleaning), standardizing, and sustaining, 5S continuous improvement involves a deeper dive into each step, fostering a more efficient and safer work environment.

For instance, 5S training can extend to implementing advanced techniques like Kaizen events, which focus on identifying and eliminating waste. This collaborative problem-solving approach encourages employees at all levels to participate in process improvements, enhancing their sense of ownership and commitment to workplace safety. By integrating lean management principles into the fabric of your operations, you not only streamline processes but also create a culture where continuous enhancement and safety are everyone’s responsibility.

Process Standardization: Ensuring Consistency and Security

Process Standardization is a cornerstone of any robust workplace safety initiative. By implementing 5S training and lean management principles, organizations can create an environment that prioritizes order, efficiency, and security. This involves systematically organizing spaces, streamlining workflows, and fostering a culture where every employee understands and adheres to clear processes.

In the context of workplace organization, 5S continuous improvement encourages regular audits and maintenance, ensuring that standardized processes remain consistent and effective. This approach minimizes errors, reduces accidents, and enhances overall productivity by eliminating unnecessary steps and redundancies. Standardized procedures provide a sense of security for employees, knowing their tasks are clear, and any deviations or potential hazards are promptly addressed.

Fostering a Culture of Safety Through Initiative Adoption

Fostering a culture of safety starts with initiative adoption and comprehensive training. Implementing 5S training, a methodology rooted in lean management, is a powerful step toward enhancing workplace organization and safety. This system encourages employees to participate actively in maintaining a clean, orderly, and standardized workspace—a key aspect of accident prevention. By integrating 5S principles into daily operations, workers develop a keen awareness of their surroundings, reducing the risk of accidents caused by disorganization or clutter.

Continuous improvement is at the heart of 5S’s success. Process standardization ensures that safety protocols are not just implemented but also regularly reviewed and updated. This dynamic approach allows for adaptation to changing work environments, new equipment, or evolving safety regulations. As employees embrace a culture of continuous improvement, they become proactive in identifying and addressing potential hazards, ultimately contributing to a safer and more efficient workplace.

Implementing a comprehensive workplace safety initiative requires a multi-faceted approach. By integrating essential 5S training, adopting lean management principles for streamlined workflows, and fostering a culture of safety through proactive initiatives, organizations can significantly mitigate hazards. Workplace organization techniques play a pivotal role in hazard reduction, while continuous improvement and process standardization ensure lasting safety gains. Embracing these strategies creates a safer, more efficient work environment, ultimately enhancing employee well-being and productivity.