Workplace safety and efficiency are enhanced through integrating 5S training and lean management principles. This system promotes workplace organization by sorting (Seiri), setting in order (Seiton), shining/cleaning (Seiso), standardizing (Seiketa), and sustaining (Shitsuke) processes. By eliminating waste, 5s continuous improvement drives safety through regular audits, fostering a culture of ownership among employees to maintain structured, safe environments, thus reducing risks and enhancing productivity.

In today’s dynamic work environment, prioritizing workplace safety is non-negotiable. This comprehensive guide explores proven initiatives for creating a safer, more efficient workplace. We delve into essential practices like 5S training, which fosters discipline and order, and its crucial role in accident prevention. Additionally, we uncover how Lean management principles streamline processes, and standardized work practices ensure consistency. By integrating these strategies, organizations can enhance safety, improve productivity, and foster a proactive culture of continuous improvement.

- Understanding the Foundation: What is 5S Training and Why is it Crucial for Workplace Safety?

- Integrating Lean Management Principles: Streamlining Processes for a Safer Environment

- The Role of Workplace Organization in Accident Prevention

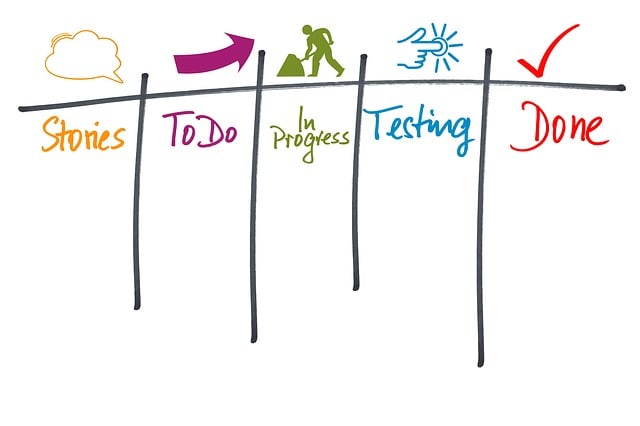

- Continuous Improvement Through 5S: A Dynamic Approach to Workplace Safety

- Standardization as a Pillar: Ensuring Consistent and Safe Work Practices

Understanding the Foundation: What is 5S Training and Why is it Crucial for Workplace Safety?

Workplace safety goes beyond compliance and policies; it’s about fostering a culture where every employee feels empowered to prevent accidents and injuries. At the core of this culture lies 5S training, a fundamental concept within lean management that emphasizes workplace organization and continuous improvement. The term ‘5S’ represents five Japanese words: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketa (Standardize), and Shitsuke (Sustain).

This training involves systematic processes to streamline operations, eliminate waste, and create a safe, efficient workspace. By implementing 5S principles, organizations achieve process standardization, ensuring tasks are completed efficiently and safely. It encourages employees to take ownership of their work areas, fostering pride in workplace organization. Regular 5S continuous improvement initiatives not only enhance productivity but also serve as a powerful tool for identifying potential hazards, thus playing a crucial role in overall workplace safety.

Integrating Lean Management Principles: Streamlining Processes for a Safer Environment

Integrating Lean Management Principles is a strategic approach to enhancing workplace safety and efficiency. At its core, this involves the application of 5S training—a system that promotes organization, discipline, and continuous improvement. By implementing the 5S methodology, organizations can streamline their processes, eliminating unnecessary steps and potential hazards. This involves Sort (organizing workspace), Set in Order (arranging tools and materials for easy access), Shine (maintaining cleanliness), Standardize (establishing consistent procedures), and Sustain (continuing the cycle of improvement).

The Lean approach ensures that every step in a process is valued, which leads to reduced waste and improved safety. Process standardization becomes more achievable when employees are trained to identify and eliminate non-value-added activities. This not only enhances overall workplace organization but also fosters a culture where everyone takes ownership of their role in maintaining a safe environment.

The Role of Workplace Organization in Accident Prevention

Workplace organization plays a pivotal role in accident prevention. By implementing structured systems and processes, organizations can significantly reduce hazards and create a safer environment for employees. The 5S training method, rooted in lean management principles, is a powerful tool to achieve this. It involves sorting, setting in order, shining (cleaning), standardizing, and sustaining, fostering an organized workspace that minimizes tripping hazards, improves visibility, and enhances overall productivity while prioritizing safety.

Process standardization is another key aspect of workplace organization. Standardized procedures ensure that tasks are carried out consistently and safely. This reduces the potential for errors and accidents, as every employee follows the same established protocols. The continuous improvement aspect of 5S encourages regular audits and adjustments to these processes, ensuring they remain effective over time in preventing accidents and promoting a culture of safety.

Continuous Improvement Through 5S: A Dynamic Approach to Workplace Safety

In today’s dynamic work environment, continuous improvement is key to maintaining a safe and efficient workplace. One powerful methodology that aligns perfectly with this goal is 5S—a lean management approach focusing on workplace organization and process standardization. This dynamic system involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing 5S training, organizations can transform their workspace into a structured, safe haven where potential hazards are minimized.

The continuous improvement aspect of 5S allows for regular audits and adjustments, ensuring that safety protocols remain relevant and effective. This proactive approach encourages employees to take ownership of their work areas, fostering a culture of responsibility and accountability. As processes are standardized, inefficiencies are eliminated, leading to increased productivity and a reduced risk of workplace accidents.

Standardization as a Pillar: Ensuring Consistent and Safe Work Practices

Workplace safety initiatives heavily rely on standardization to ensure consistent and safe work practices across all teams and departments. By implementing processes like 5S training, which emphasizes workplace organization and continuous improvement, companies can create a structured environment that minimizes risks and promotes efficiency. Lean management principles, focusing on eliminating waste and streamlining processes, complement these efforts by fostering a culture of safety and productivity.

Standardization goes beyond initial setup; it’s an ongoing process. Regular 5S assessments and continuous improvement initiatives ensure that safety protocols remain relevant and effective as the workplace evolves. This holistic approach, integrating elements of 5S training and lean management, is crucial in maintaining a safe work environment that adapts to changing demands and technologies.

Implementing a robust workplace safety initiative requires a multifaceted approach. By integrating 5S training, Lean management principles, and prioritizing workplace organization, organizations can create a safer environment. Continuously improving processes through 5S and standardizing work practices ensure consistency in safety measures. These strategies collectively foster a culture of safety, enhancing productivity and well-being for all employees.