The 5S Framework is a lean management tool for enhancing workplace organization and productivity, involving sorting, setting in order, shining (cleaning), standardizing, and sustaining. This method streamlines processes, reduces waste, and fosters continuous improvement through standardized procedures, benefiting various sectors like healthcare and logistics. Regular audits, data tracking, and KPI monitoring ensure successful workflow changes and adaptability to evolving demands.

In today’s competitive business landscape, systematic workflow improvement is crucial for enhancing productivity and fostering a culture of excellence. This article guides you through powerful strategies, including the 5S Framework for Organization and Lean Management techniques, to revolutionize your workplace. Discover how process standardization and identifying inefficiencies can drive continuous improvement. Learn best practices for implementing successful changes and measure their impact. Enhance your workplace organization with this essential 5S training for sustainable growth.

- Understanding the 5S Framework for Organization

- Lean Management: Streamlining Workflows Efficiently

- Standardization: The Key to Continuous Improvement

- Identifying Inefficiencies in Workplace Processes

- Implementing and Measuring Successful Workflow Changes

Understanding the 5S Framework for Organization

The 5S Framework is a powerful tool for cultivating workplace organization and driving systematic workflow improvement, rooted in lean management principles. This methodology involves five key disciplines: Sort, Set in Order, Shine, Standardize, and Sustain. Through 5S training, employees learn to visually manage their workspace by eliminating clutter, establishing clear processes, and maintaining a clean, efficient environment. By implementing process standardization through 5S, organizations can enhance productivity, reduce waste, and foster a culture of continuous improvement.

Each ‘S’ in the framework represents a step towards creating a streamlined, optimized workplace. For instance, sorting involves categorizing items used daily from those that are occasional or unnecessary, while setting in order ensures everything has its designated place. Shining includes thorough cleaning and inspection to maintain a high standard of hygiene and visual clarity. Standardization, achieved through consistent application of the 5S principles, ensures processes remain efficient over time, making it easier to identify and rectify any deviations or bottlenecks.

Lean Management: Streamlining Workflows Efficiently

Lean Management is a powerful approach to streamline workflows and optimize processes, ensuring every step adds value. At its core, it advocates for eliminating waste, which can manifest in various forms, such as unnecessary movements, overproduction, or defects. This philosophy has its roots in manufacturing but has since been successfully adapted for diverse industries, including healthcare, logistics, and service sectors.

The 5S training method is a cornerstone of lean management, focusing on sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing these principles, organizations can achieve remarkable workplace organization and efficiency. Process standardization ensures that tasks are carried out consistently, reducing errors and improving quality. This systematic improvement approach fosters a culture of continuous learning and enhancement, enabling businesses to stay agile and competitive in today’s dynamic market.

Standardization: The Key to Continuous Improvement

Standardization is a cornerstone in any systematic workflow improvement strategy. By implementing 5S training and lean management principles, organizations can achieve remarkable efficiency gains. This involves organizing and structuring work processes to eliminate waste, reduce errors, and enhance productivity. A well-organized workplace, where every tool and resource has its designated place, sets the stage for continuous improvement.

Process standardization plays a pivotal role in this journey. It ensures that tasks are performed consistently, allowing for better quality control and predictable outcomes. Standardized procedures enable employees to focus on value-added activities, fostering a culture of efficiency and innovation. This methodical approach, backed by 5S continuous improvement techniques, ultimately leads to improved job satisfaction and overall operational excellence.

Identifying Inefficiencies in Workplace Processes

Identifying inefficiencies in workplace processes is a critical first step in implementing systematic workflow improvement. Organizations often overlook these hidden bottlenecks, which can hinder productivity and create unnecessary strain on resources. By adopting methodologies such as 5S training and lean management, businesses can uncover areas of improvement and optimize their operations. This involves breaking down each process into its constituent parts and examining every step for potential redundancies, delays, or inefficiencies.

Workplace organization plays a pivotal role in achieving seamless process standardization. A well-organized workspace ensures that employees have easy access to the tools and materials they need, reducing wasted time spent searching. 5S continuous improvement—a system emphasizing sorting, setting in order, shining (cleaning), standardizing, and sustaining—is one effective approach to fostering a culture of efficiency. This method encourages regular reviews and adjustments, ensuring processes remain streamlined as the business evolves.

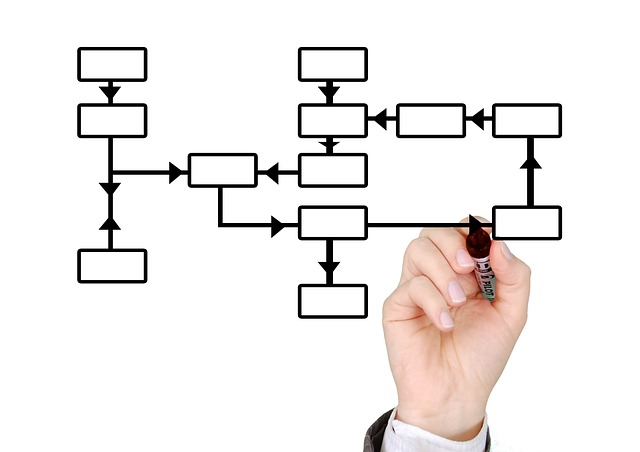

Implementing and Measuring Successful Workflow Changes

Implementing and measuring successful workflow changes is a crucial step in any systematic workflow improvement initiative. Starting with 5S training, which emphasizes workplace organization and process standardization, can significantly enhance overall efficiency. Lean management principles, focusing on eliminating waste and streamlining processes, should then be integrated to ensure continuous improvement. Regular audits and data collection are essential tools for gauging the effectiveness of these changes. By tracking key performance indicators (KPIs), organizations can identify areas where further optimization is needed.

Measuring success involves comparing current performance against established benchmarks or target levels. This data-driven approach allows managers to make informed decisions, adjust strategies as necessary, and communicate the tangible benefits of workflow improvements to all employees. Continuous improvement is a journey, not a destination, and leveraging tools like 5S and lean management ensures that organizations stay on track, adapt to changing demands, and maintain a competitive edge in their respective industries.

By integrating the 5S framework, lean management principles, and consistent process standardization, organizations can achieve remarkable workflow improvements. These strategies empower teams to identify inefficiencies, streamline operations, and cultivate a culture of continuous enhancement. Through practical implementation and measurable outcomes, businesses can transform their workplaces, leading to increased productivity, reduced waste, and enhanced overall organization. Embrace these methods as a powerful trio for driving successful systematic workflow improvement.